Bert finds a commonly missed airflow issue when out to do a leak detection on an A/C system. Jessica also comes along for filming and to talk about tools.

When the air handler is packed into a tight space, the front and back insulation can pull against the system. That insulation gets pulled against the blower, which can result in airflow problems. The solution to that sort of problem is to tighten down the insulation and keep it from flapping back up against the blower.

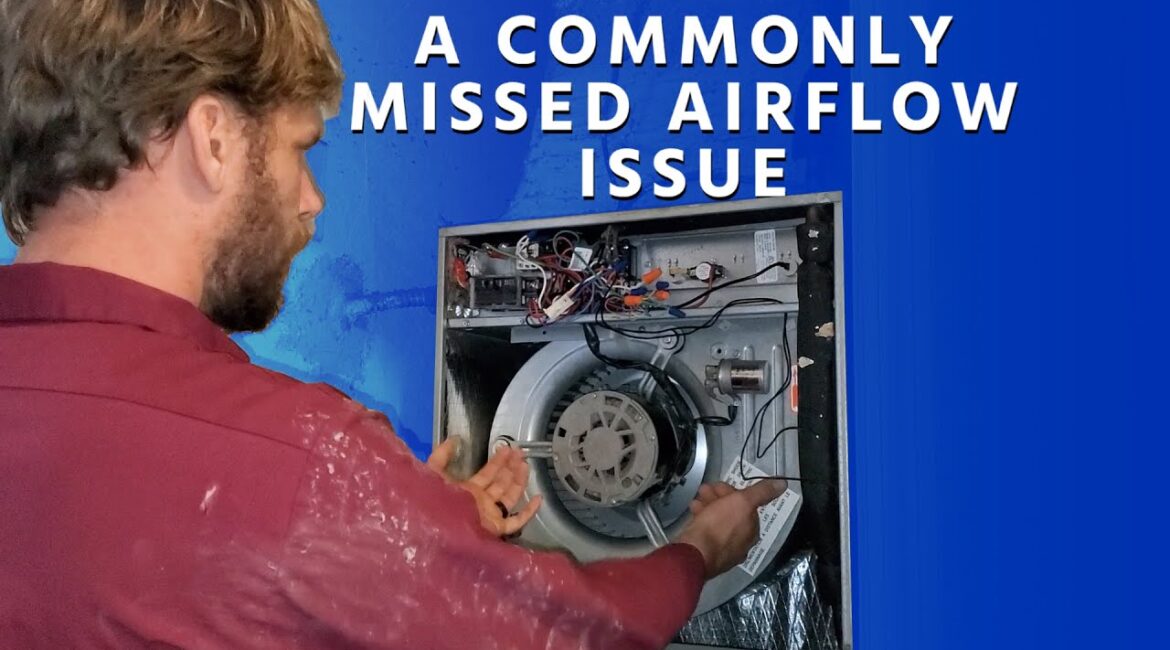

To access the back insulation, you’ll need to pull the blower wheel out. In this case, the washers are slightly bigger than the wheel and held in by three screws. When we remove the screws, the whole blower assembly can slide right out.

Bert also comes across an upside-down screw with a very tight access space at the top between all the wiring and the relay. Making sure that the power is off, he gets the wiring out of the way to make the space a little less tight. When the screw comes out, Bert decides to leave it out, as four screws will work well enough to keep the blower assembly in place.

The insulation looks pretty rough in the back, so Bert decides to glue it down on the flat sides and tape the corners. When taping the corners, Bert creases the tape BEFORE applying it to make the taping process easier.

Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/.

Learn more about the 2022 HVACR Training Symposium at https://hvacrschool.com/symposium/.

source

Truer words have never been spoken Jessica, "when you have the proper tools, the job goes easier".

Is there a link to that ratcheting wrench? @2:38

Thanks Jessica

Bert getting schooled by a newbie 😛👌 way to go Jessica. 😎👍

You need an angle attachment for your drill and the mini ratchet from klein tools. Trust me 😉

Always leave it to the homeowner to have the TV on blast 💥

Isn't that why you're supposed to put that insulation with foam side towards the blower? My blower box has the silver backing on the outside, and inside only foam. So I'll never encounter this issue. But my blower is also newer, so, idk.

48 yr Ac vet here. Excellent advice brother!

👍

That plenum is terrible. Whoever 4pieced and applied mastic to that unit should be fired … quick tip never seal electrical penetrations in the wall with mastic either .. 😬

Nice job 👏

I had a similar problem with a roof top unit that the armaflex insulation from the interior got sucked in the blower and the unit was only a month old.

It’s a totally different business in airhandlerlland. I’ve never seen anything like this happen on a furnace.

This screw is never never to be seen again 😀

The tape is going to come loose in the future, make all kinds of noise. causing a nice little callback…Tape is never permanent solution.

"That screw is never going back in" 😂 Omg I just don't understand why they have unnecessary screws in some units! Just to piss service tech off I guess haha

Those small ratchet wrenches can be versatile. The 1/4 &5/16 can be used on the shaft of 1/4 bits like you showed and the 5/16 works on the hex section of many multi bit screw drivers. A 3/8" wrench works on the other hex section and the bolster some screwdrivers have, but rather than carry an extra ratchet, you can use your 3/8" flare nut wrench needed for thermocouples on many gas valves.

thanks. nobody does this , they just screw on the cover and forget it. I bet theres only a half inch of clearance

How about a "Jessica Supervises a Bert Truck and Tool Bag Remodel"?

Jumbo windshield sun shield cut to fit.. 10 min. Leave the glue for the kids.

Excellent tip on what to watch for. That type of insulation is absolutely prone to fail and just a matter of time. Nice work! Good example of a technician taking the blinders off 👁👁.

Good job…. people don't realize how much air loss there is when that condition occurs

Hey Bert you make the perfect dual with Jessica working together😅

There for a leak detection but go ahead and take the time to secure the foil? Standard practice to go the extra mile? Maybe they ok'd it with the customer for extra time. It would be awful to leave as is but for that sizeable of a job and you're not getting paid extra…….

i would of just used pliers and turned it loose from the bottom half of the screw if its never going to be used again who cares if its stripped. but if your penny pinching and plan to re use that screw elsewhere dont.

Jessica you rock 🙌🏻🙌🏻🙌🏻🙌🏻🙌🏻 I always have the right tools 🧰

Yet another excellent tip from you guys. Thanks!

Excellent work! Would love to see a demonstration of replacing wet insulation with foam sheets like what was discussed during the last symposium.

Boot bars or S lock work really good too

Could u have just taped it up without the glue or is the glue necessary?

good video! fuzzy face

Thanks for the videos!

🍺🍺🍺🥃🥃🎯🏌🏻♀️

Stay safe.

Retired (werk'n)keyboard super tech. Wear your safety glasses!

I’m so glad to see Jessica showing Bert how things get done!!

👍

Great job Sir.

No sticky back pins for holding the insulation on?

"ratcheting nut driver", 😯 wow… How are you even going to make a statement about "have the proper tools" when you don't even know the name of the tool you're speaking about? Lmao 🤣

Spray glue is smart. Never thought of this.

I ran into that same issue today on that exact model while I was diagnosing a no heat call. What a coincidence that this video popped up as soon as i opened YouTube!!! Is Gooble watching me work now? Only the algorithm knows…

Someone smack an engineer!

Find the leak?

Who carries spray adhesive?