Get a Free Compressor Troubleshooting Guide – https://offers.refrigerationmentor.com/free-guide

Make sure if you ever have a bad electrical failure or compressor burn you should always replace or clean the accumulator as best as possible so it does not lead to a second or third failure.

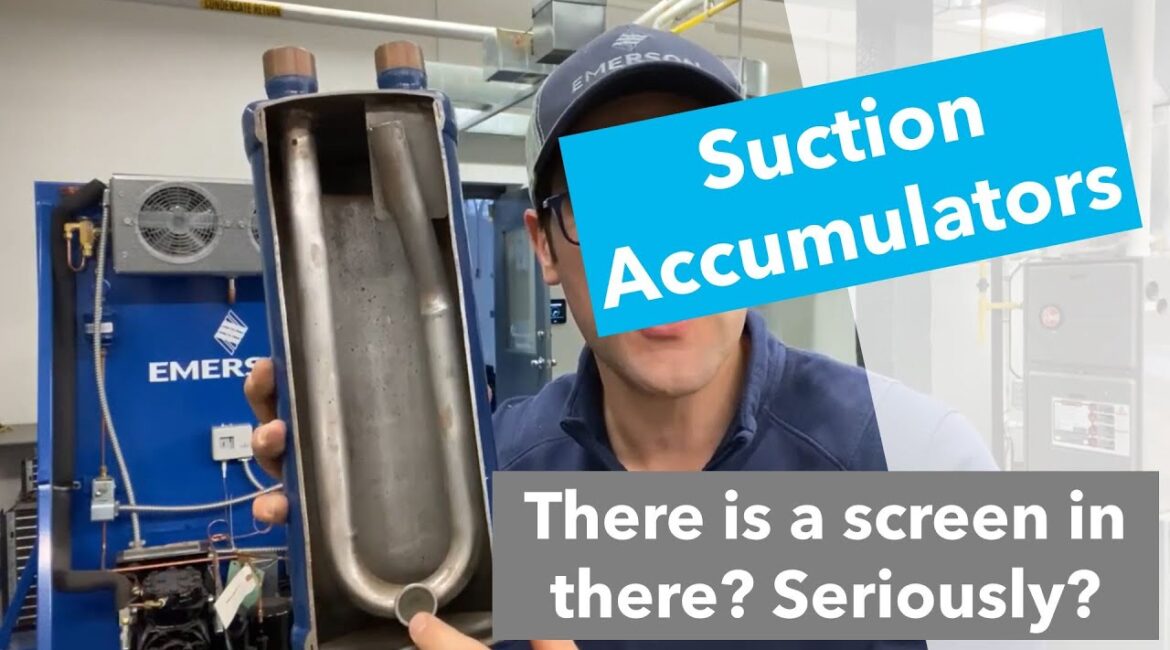

Any time a system is running and liquid refrigerant does not boil off in a refrigeration or air conditioning system, it may cause damage due to refrigerant slugging, loss of oil from the crankcase, or bearing washout. To help protect against this condition on systems, a suction accumulator may be necessary.

Flooding can occur on heat pumps when the cycle is switched between heating and cooling, reversal before and after defrost, and during low ambient heating operation. Suction accumulator should be on any system that is at risk of flood back.

Flooding can happen during normal pressure equalization when the system shuts off in systems with large refrigerant charges.

Systems that have hot gas defrost are also subject to liquid flooding either at the start or termination of the hot gas cycle. Compressors on low superheat applications such as low-temperature cases or liquid chillers are susceptible to occasional flooding due to system-related issues.

The accumulator’s function is to stop and store liquid refrigerant before it reaches the compressor crankcase. It should be located in the suction line between the evaporator and the compressor and must be designed so that oil can return to the crankcase so that oil does not get trapped in the accumulator.

Check out AE11-1147 – https://webapps.emerson.com/online-product-information/Publication/LaunchPDF?Index=AEB&PDF=1147

source