In this class, Bryan gives the Kalos techs a refresher and goes over the basics of static pressure. He also differentiates between utility manometers and precision manometers, covering their appropriate uses.

Utility manometers are your typical standard service manometers; they are designed to measure pressure in inches of water column (“WC, “H2O, or inWC). Inches of water column are smaller units of measure than PSI, and they’re ideal for static pressure and gas pressure. Some utility manometers have one port, and others are dual-port manometers. Single-port manometers require you to zero them with the hoses on before taking the measurement. (Accurate zeroing is very important, especially as pressure continuously changes with the weather.) Dual-port manometers are often used for measuring a pressure differential, and zeroing is typically less critical because there is already another baseline for comparing the pressure.

There is no such thing as “zero pressure.” The closest we can get to “zero” pressure is 14.7 PSI, atmospheric pressure, so zeroing out single-port manometers is critical.

Precision manometers use Pascals instead of “WC, which is a much smaller scale. We use precision manometers to measure duct leakage or envelope leakage (such as through a blower door test). We can also use the tiny Pascal scale to measure pressure imbalances between rooms and mitigate pressurization/depressurization problems.

Static pressure probes look an awful lot like pitot tubes, which have tubes within tubes. A pitot tube takes a measurement that’s a combination of static pressure and directional force. Pitot tubes then subtract the static pressure to yield only the velocity pressure; these tools require precision manometers to do their jobs properly. Pitot tube usage is more common on the building science side of the industry than HVAC service.

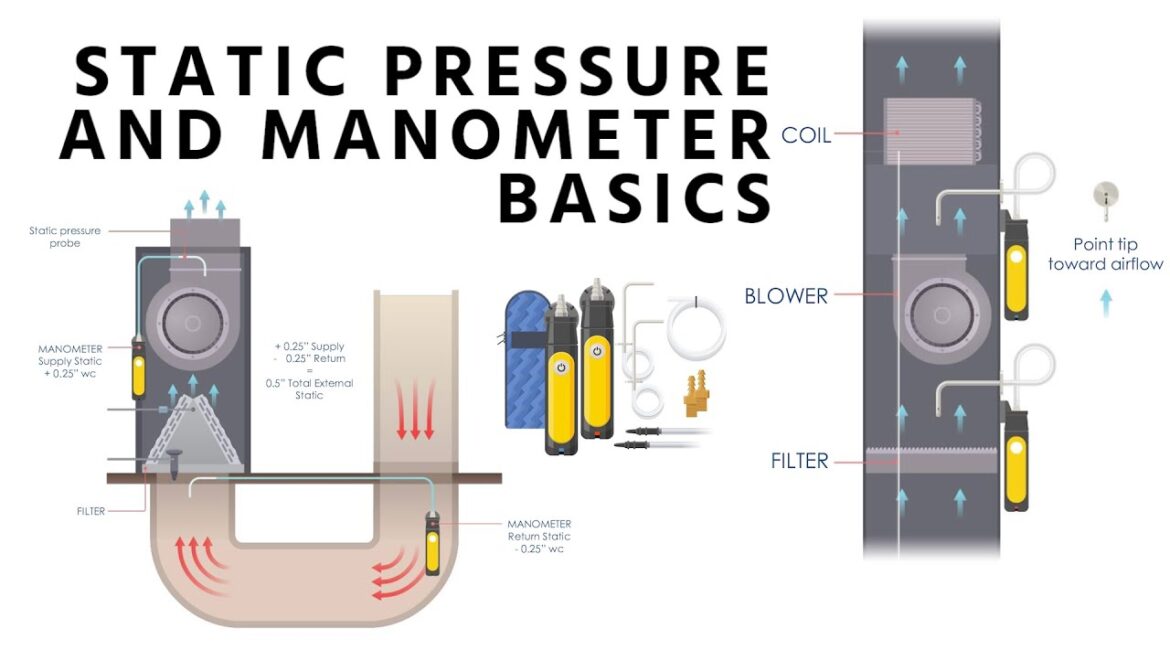

Static pressure probes each have a closed end at the tip and some side ports, and they only measure static pressure. The probes face the opposite direction of the airflow and measure the force exerted in all directions (against the walls of the duct). Static pressure can be either positive or negative in reference to the atmosphere, and we typically measure it by putting one tube in the return before the blower and the other above the blower in the supply plenum in a fan coil or handler on a heat pump or straight-cool A/C (or below the coil on a gas furnace). In gas furnaces, the coil provides a pressure drop and is separate from the actual unit.

The rated static pressure can be found on the data tag; a static pressure that differs from the rating will affect the system’s performance (though there is typically an operating envelope). If the static pressure is higher than the test static on the data plate, a variable-speed blower will have to ramp up to maintain the airflow, increasing operating costs and the amp draw while negatively impacting the motor’s longevity. Filter changes can cause the static pressure to change over time. You can also measure pressure drops over the filter and evaporator coil to isolate problems with filters or coils.

Static pressure is NOT airflow; it’s a pressure measurement, but it can be an indicator of airflow. Before we can measure the static pressure accurately, we need to make sure the system is producing the proper airflow (high-stage, no dehumidification mode). Although checking static pressure isn’t something we need to do on EVERY call, it’s worth checking when there are airflow complaints. Total external static pressure, supply, and return static are all worth checking to see if there are restrictions across filters or coils or other possible airflow problems.

Filters can cause many problems, and static pressure readings can help you pick up restrictions caused by filters. Larger filters (4″) with greater surface areas tend to create far less of a pressure drop and last longer than shallower filters (1”), which can clog and restrict airflow quickly.

Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/.

source

This is an awesome Video Bryan. Very informative. I’m gonna pass this along to our techs. One the best detailed videos I’ve seen to properly explain Static Pressure. Hope all is well buddy.

I disagree with checking external static pressure on a high speed. And the reason being is if we design a duct system with a blower at a .5 inches of water column for a specific friction rate, why would I change that if as a result I’ll have more air flow and higher static?. It’s the same weird concept where people are changing the fan speed to high in order to check CFM on a gas furnace. Why would you add extra work just to verify air flow? Blower performance charts are usually available. I could go on all day about it. Thanks for your videos.

Thanks for your hard work

Thank you very much Bryan!!!

This is defiantly one of if not the best explanation of static pressure, Thanks once again Bryan and team

Great info. Thanks Bryan.

Thanks for another great and informative video!

I've recently had to go through a crash course on using static pressure to identify ducting problems. I work in commercial HVAC and if I were to use the TEC Tru Flow with all the adapter kits, it would get very expensive with all the extra adapter kits. Majority of the RTUs I work on have 4 filters or more per RTU. Can I get away with using one adapter plate and placing in the middle of the filter rack or return ducting?

I own Testo 510 and Fieldpiece SDMN 6 stand alone manometers. I find the SDMN 6 drifts quite a bit, which I believe is due to not being temperature compensated like Testo. Does the Fieldpiece wireless manometers drift as well?

My 6 year old has been making us binge watch your channel lately 😅 he loves it!

Not a word about a Magnehelic gauge?

Thanks again for the videos!

🥃🥃🍺🍺🍺⛳️🎳

Stay safe.

Retired (werk'n)keyboard super tech. Wear your safety glasses!

Good video I love this content

Excellent video ‼️

Thanks ‼️

Thanks sir my improving knowledge hvac your channel thanks allot 🙏🇮🇳

Wonderful

Great video. I do HVAC at a hospital and we do a LOT of air balance and static pressures. We always take a static pressure differential across final filters on the maintenances. Recently I took a bunch of Pitot readings to evaluate plugged chillwater coils to see if they need replacement.

It was definitely a learning curve.

Enjoyed vid. After watching, clear as mud. I'll watch a few more times…. Thanks for posting this info.

Have you done an AprilAire filter review?

Great Video. Amazing presentation!

👍

Excellent lead into using DEEP PLEATS HIGH MERV efficient filters on Correct size. Of course measuring pressure drop or following the chart printed on the side of the filter and always recommend upsizing.