Get a Free Compressor Troubleshooting Guide – https://offers.refrigerationmentor.com/free-guide

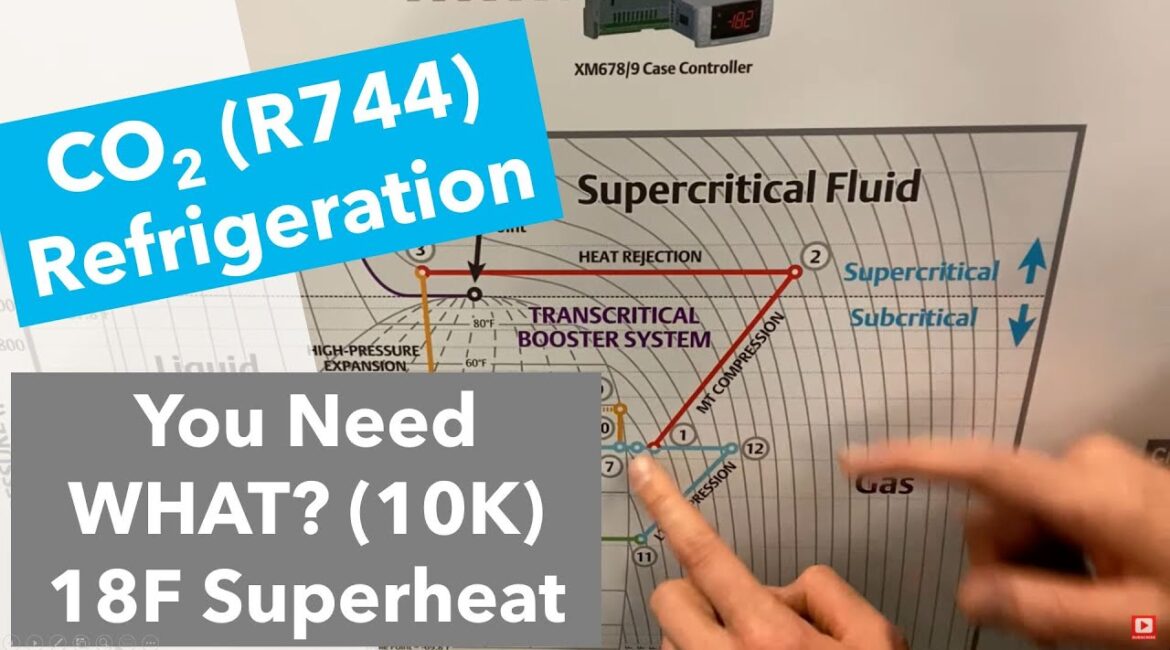

It is so important on every compressor out there to have superheat or you are risking having the proper lubrication for that compressor. Oil dilution. This can cause bearing damage/scoring! A minimum of 18°F (10K) superheat is recommended for MT Transcritical at compressor suction inlet is required at all operating conditions to avoid oil dilution with CO2 (R-744). For Low Temperature Subcritical models, the compressor operating superheat, at suction inlet, should be maintained above 36°F (20K) to avoid oil dilution. However, controlling the return gas temperatures to maintain compressor discharge temperatures below 250°F (121.1°C) is recommended, especially at high compression ratio conditions (high condensing and low evaporating temperatures). The compressor superheat should be controlled at a balanced level to not only avoid oil dilution in the compressor but also maintain a compressor head discharge temperature below 310 °F (154°C), especially at high compression ratios (high condensing and low evaporating temperatures)

Check out the full manual here – https://webapps.emerson.com/online-product-information/Publication/LaunchPDF?Index=aeb&PDF=ae1396.pdf

source