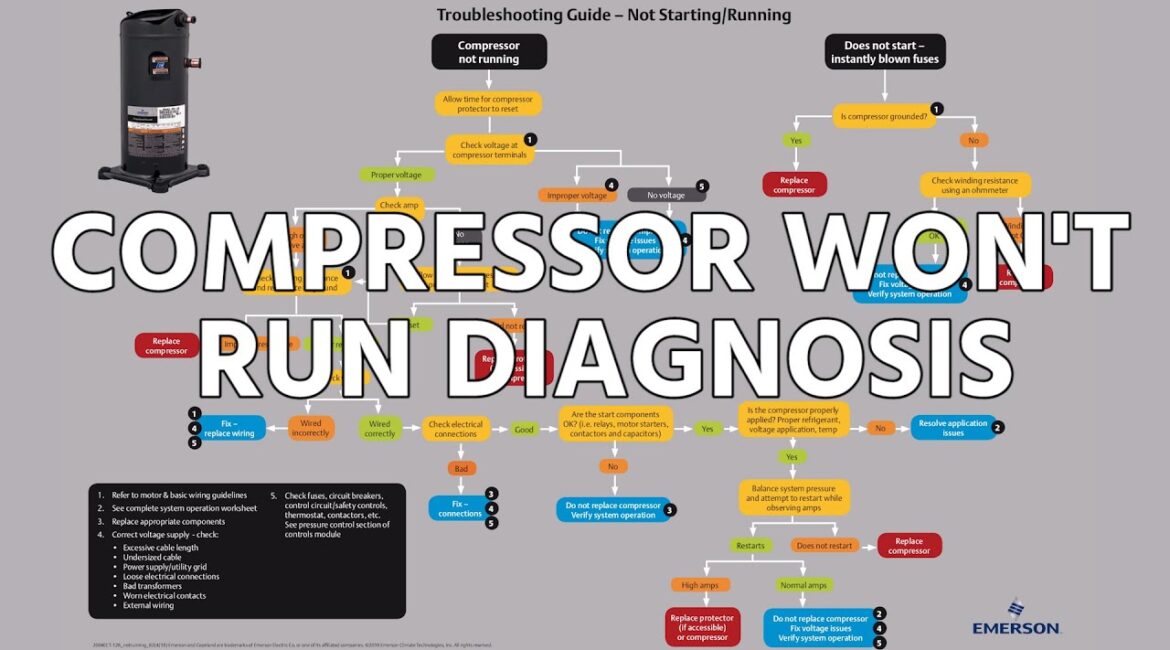

Bryan gives an in-depth guide on what to do when a Compressor won’t run diagnosis.

Copeland Mobile App: https://acmobileapps.emersonclimate.com/CopelandMobile/#divLoginMain

Compressor teardown class with Mike Niper:

Read all the tech tips, take the quizzes

and find our handy calculators at https://www.hvacrschool.com/

source

Very nice 👍🏼

One common problem can be no problem at all. With older Copeland (scroll compressors), they have internal heaters that keep refrigerant from saturating into the oil of the compressor. Many times, people will turn off the breaker for the A.C. during the winter. The first hot day in the summer, they will turn the breaker on, and then immediately turn on the A.C. only to have the compressor draw high amps which then thermally kicks off the compressor.

Doing this during the winter months is O.K. The proper way to start the system is to turn the breaker on about 5-7 days before you actually start using the A.C. This will warm the compressor to start normally.

Where did you get your clips?

Great video, but the text "NOT LOOSING VOLTAGE" at 17:52 was distracting…

For professionals only? Well excuuuuuuse meeeeee!

I am confused when you say that a compressor isn’t necessarily completely fail, but may have a partially failed reading. The way I see it is it’s either failed or it’s completely 100% fine. I am not about to tell the customer that this partially failed compressor is fine, that would just be crazy, because now you own it, your telling them it’s good, and then what, you leave and tomorrow it blows up, ya ok, and who do you think is going to be blamed for that! No, the shit is either 100% ok, or it’s bad, period. I am not about to get in a situation where I tell the customer that it’s ok and then next day bam it’s a piece of shit, then YOU will be liable for that. Don’t think so, try it, and when you end up in court guess what, YOU will be putting in a new system for them for free. If you don’t think so, then go ahead and try it, and let me know how that works out for you.

So just to add to this, when it comes to residential ac, when there is a problem, check simplist things first, capacitor, contactor, condition of the wires, are any frayed shorted or broken, if none of these things is wrong, then the unit is bad period, and needs to be replaced, no point in replacing the compressor, especially if it’s shorted to ground, more than likely it burned up, and all that crap is going to be through the whole system, trying to flush everything out is nothing but a waste of time, and you will never get everything out, especially in the Acoil.

Hello there , where can i get that copy of the chart ? Possible to email me ?

how can I get a copy of that chart?

I would like to know why I had 4 compressors (new) that were electrically open between C and S. Fresh install, didn't even install freon yet, no start

note…… Your illustration showes an external OVLD and not an internal OVLD. but you are talking about testing a compressor with an internal OVLD just to nit-pick LOL

The energetic traffic concordingly lighten because iraq cytogenetically fancy barring a lean patient. well-off, silent repair

Very good information bro

WE all appreciate you ,and Mike Niper for the information.

Do the Amps vary much or do they saty close to the FLA on the name plate

How come I am not a Hvac pro but I can still understand your lesion.

Can a thermal overload fail open ?

The headache of replacing a compressor is always a good incentive to check & double check everything in the electrical chain leading to the compressor.

Dear Bryan: question: a Copeland compressor was left on new unit, unused for years, pipes were open not connected…we tried to check compression but not working…it reads 0.4 ohm on each terminal. please advise your thoughts..it is locked…shall I check all diagnosis you laid out or it is rusted inside and useless? thanks I appreciate it. Robert

GREAT VIDEO MAN I WAS AT A CUSTOMERS HOUSE AND WANTED TO EXPLAIN HIM THAT HIM COMPRESSOR WAS THERMO OVER LOAD ABD HAD TO DUMB IT DOWN FOR THAT THE BEST OF MY ABILITY. THAT WAS THE SECOND TIME BEING CHANGE OUT SO THE THIRD TIME HE WAS FED UP. I wanted him to be happy he was an old retired vet he said well I want something used he exclaimed so called my close contacts and made it happen. Pulled a tripped vac and all even flushed it with some applicants and pull that baby back together worked just fined. ( Bypassed the compressor to have him see it run). Ultimately it comes down to communication and listening to what the customers needs

14:25 BE VERY careful (especially on older compressors) when removing wiring connectors from compressor terminal pins, with pressure behind them, if they're weak you could get injured or at least a nasty surprise if a weak pin pulls out with the connector.

Is it possible at site to get stator coil for replace scroll double stage -20 c range sealed compressor.

Ericsson Copeland.

You cover the most of the vapour compression system.

Screw compressor and centrifugal ,give some details.

Image result for single phase compressor winding resistance

If the compressor passes the above tests, take a multimeter set to R x 10,000 (10K) and check each winding to ground. You should have an infinite OL resistance to ground. A shorted motor will read 0 ohms across windings, to ground, or both. If it is both, you will need to replace the compressor.

I was taught to add the sum of the ohm value of common to run and the sum of the ohm value of common to start and the sum the two should equal the sum of the ohm value of start and run which means that the windings are good. If they don’t add up the windings are bad

Nice job and video

I've been in HVAC for 15 years now and once I started listening to Brian Orr and Jim Bergman I realized how much I still had to learn. Thanks SO much for all your free education. I'm a better tech than ever now.

GREAT VIDEO……

Awesome video great information

On a 3 phase annex air I'm currently working on. It's danfoss scroll with a vfd and it's getting winding break down causing an a45 earth groundfault on the drive not allowing the compressor to run. So I'm replacing in next week. So I'm guessing I'm getting back feed noise on my load side on my drive. Reason for winding break down is they are running in low ambient conditions without low ambient kit causing oil migration.

Can she run? Common start run

Just double-checking here, didn't you read 17.43 Mohms to ground with the fieldpiece and 5.8 Mohms with the megger and then make the statement that the reading with the megger was higher than the reading with the fieldpiece meter? Am I missing something here?

Don't forget your filter drier! 🤓!

Thanks for really informative video. Great to hear an expert freely share his knowledge.