Bryan with HVAC School goes over AC pressures, subcooling, and superheat in his troubleshooting mindset presentation from the BTrained HVAC training event in Birmingham, AL. Bryan also talks a bit about his educational photo-sharing app, MechPic.

The suction pressure and suction saturation give us an idea of the refrigerant’s boiling temperature. Evaporation happens at the surface and not necessarily at the boiling temperature; on the other hand, boiling happens throughout the entire substance and occurs at the boiling temperature. So, the “evaporator” is really a heat absorber where boiling occurs.

A rule of thumb for suction saturation is that it should be around 35 degrees below the indoor ambient temperature at 400 CFM per ton. That differential or temperature split, also known as the design temperature difference (DTD), is typically 30-35 degrees in high-humidity markets that use 350 CFM per ton like Florida and Alabama, where the conference took place. Lower suction pressures generally result in a higher DTD, and higher suction pressures usually result in a lower DTD.

When we look at head pressure, we’re actually learning about the condensing temperature over ambient (CTOA). The CTOA is the temperature split between the outdoor ambient temperature and the condensing temperature. In general, CTOA tends to fluctuate a bit more than evaporator DTD, but a rule of thumb is that it should be about 15-20 degrees above the outdoor ambient temperature. SEER ratings may also affect CTOA.

A ratio of head pressure to suction pressure is your compression ratio. Higher compression ratios tend to lead to reduced compressor performance (moving fewer BTUs).

Even though we tend to see high head pressure as the main problem to avoid, we should be aware that low head pressure is possible. There needs to be an energy or pressure differential for matter to move from one place to another, and we’ll have trouble moving refrigerant if the head pressure is too low. The most important thing is to make sure that the system is working in accordance with its design.

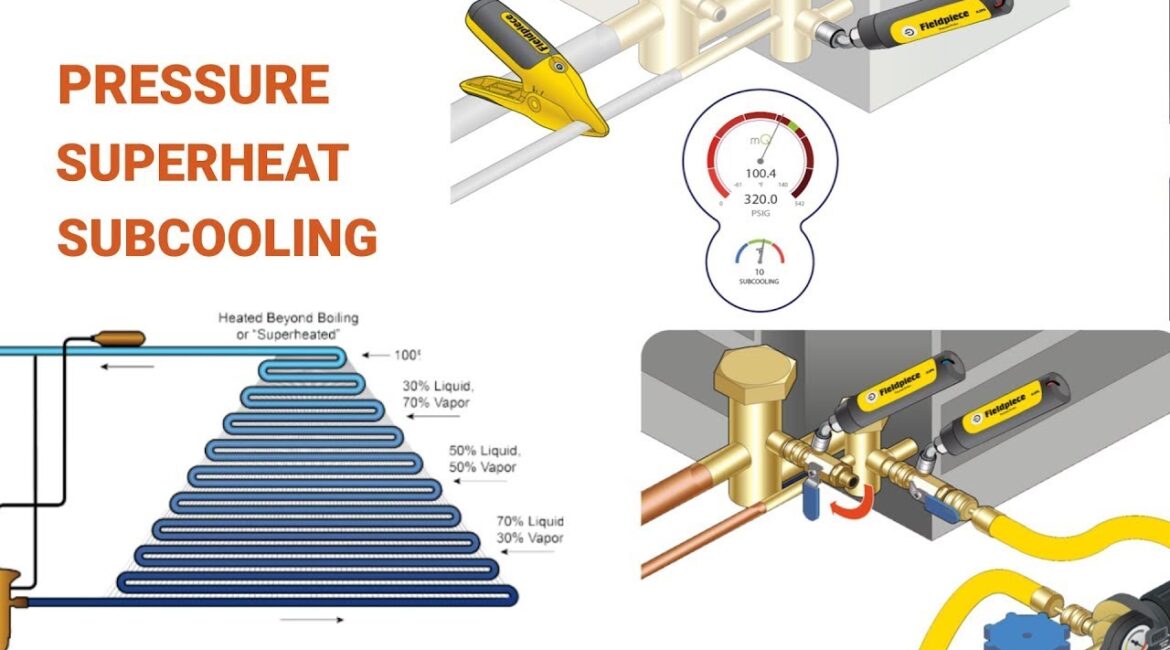

Superheat is the degrees a vapor is above its saturation temperature, and it really tells us the amount of liquid that’s stacked in the evaporator. However, the evaporator and compressor superheat could be quite different due to heat gains in the suction line. Generally, we want to see 10 degrees of evaporator superheat (+/-5 degrees) on many AC systems. The TXV is supposed to keep superheat constant; however, some possible system problems can affect superheat beyond the TXV’s control (such as significant liquid line restrictions, though there are exceptions to that example).

On the other side, subcooling refers to the temperature of a liquid below its saturation temperature. In an HVAC system, subcooling indicates how much refrigerant we’ve “stacked” in the condenser; lower subcooling indicates that we have little liquid refrigerant stacked in the condenser, and higher subcooling indicates that we have a lot of liquid refrigerant stacked in the condenser. (There can, but not always, be temperature drops across liquid line restrictions.) Refrigeration systems with receivers don’t necessarily have to rely on subcooling values to indicate refrigerant storage (a rule of thumb for residential A/C systems is typically 10 degrees +/-3). When we measure subcooling, we really want to know if we’re feeding the metering device a full column of liquid. If we want to increase subcooling, we can do that by reducing the liquid temperature via mechanical subcooling or increasing the condensing temperature. (However, we don’t want too much subcooling.)

When we use the manufacturer’s specs to set our superheat and subcooling, we might actually be reducing the equipment performance, so we have to know exactly what our goals are.

Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/.

source

A very good follow up! I like it!🙂

This guy has the best nipples in the buisness.

If you oversized piston would that lower subcooling, superheat and delta?

I am also 48 year old student as i am watching in your class 🤔 and your new subscriber also 🌹

Very interesting

OH SNAPS! I got light bulbs going off!

Where would I start with you’re vids ? I’m an apprentice

You have to tie it with psychrometric charts to be accurate of what you are saying. CFM, moisture content of air on both evaporator and condenser affect the heat exchange,. Rule of thumb is not accurate way to define heat exchange and cooling/heating results. Heat exchanger surface areas are also to be included.

5:31 – The cat's outa the bag. Is this app available?

Brian, can you share your powerpoint? I'd like to have this class with my techs.

HVAC school at min 17’21” you mentioned 20 degrees superheat is too high in a 10ft line set but Copeland minimum is 20 degrees to ensure no liquid comes back. I believe your compressor SH overrides Evap Sh in this example. If you want 10 degrees in the evap you could risk flooding back. So you asked if 20 degrees SH is good back at the compressor and that would be the least you’d want at the compressor it should be that or higher all depends on length of lineset

Hey Brian how do I find Mech pci ?

Russ

Hey brian, maybe you can help me out with a small disagreement, I was telling another tech about what another one does when he cleans a condensing coil with a water hose while the unit is running, one its counter productive to try and hose off the coil while its sucking in won't get clean , but that it's not good for the system because your now stacking the condenser coil with liquid by doubling the amount of subcooling going on from air and water, he says there not a problem, so I'm asking it is detrimental to the system to do it that way, would I be correct?

I personally think alot of these guys should start talking more about window air conditioners, central air and portable air sucks, window units are the best, window units are always needed more than the others…

Been in the trade 24 years, I love listening to your videos before work during my work out or morning walk, knowledge is power. Your videos reaffirm my work. Please keep spreading the love – one day I hope to be at one of your seminars. God bless, your a legend to the hvac family.

very difficult sir

You cut it when it made sense!🤣🤣🤣

Thanks again for the videos.

🥃🥃🍺🍺🍺🎳⛳

Stay safe.

Retired (werk'n)keyboard super tech. Wear your safety glasses!

Bit of trivia from hi-fi audio. Generally, they pitch is the amplifier has 30db and that means is amplifies the signal 30 times. It just so happens 30db is about 30 times. It's really 29.xx db, but it just happens at that point, 20 db is not 20 times, etc.

Great info. Bryan. Thank you.

When everyone raised their hand saying they were in a humid market, I thought to myself, Edward Janowiak would disagree.

Hi, Bryan. I appreciate you for the great works you guys are doing. I would like to know if you have an accelerated HVACR training program? Alternatively do you have a packaged and elaborated videos for a new technician? Trust you will give these questions a response. Thanks.

My brain is like 🧠🔥💥💨🛠💵🔮🆒🍑🆗got it 🤓🥸🤥

I can never watch your videos enough even if it’s a repeat on the same topic that you have done before I always learn something new on a method of teaching other people through your videos.

As you grow and learn and improve in your industry I grow and learn and improve in my industry by watching your videos.

I want to become an HVAC instructor as I approach retirement in a local HVAC college and adopting your methods and style of teaching along with Ty and Craig and Chris combining all these styles and methods together will definitely excel my students and myself in a teaching and learning environment.

👍. Thank you for all your efforts and time involved in producing these videos so we can all share and pass the knowledge along

Excelsior My Friend ! Smashing through all your Videos…

Cooling season if fast approaching and I'm all about Complete solutions found efficiently and professionally.

I appreciate this video . help a lot

Great video as usual!